Wrench Manufacturer

- FOXWOLL provides a full range of wrench wholesale solutions.

- Provide a variety of different styles of wrenches to meet your different work needs.

- Using high-quality materials and special surface treatment, anti-corrosion.

- 16 years of experience in trade and export, properly handling various emergencies.

Get an Instant Quote

We typically reply within 3 hours.

Provide A One-Stop Wrench Shopping Experience

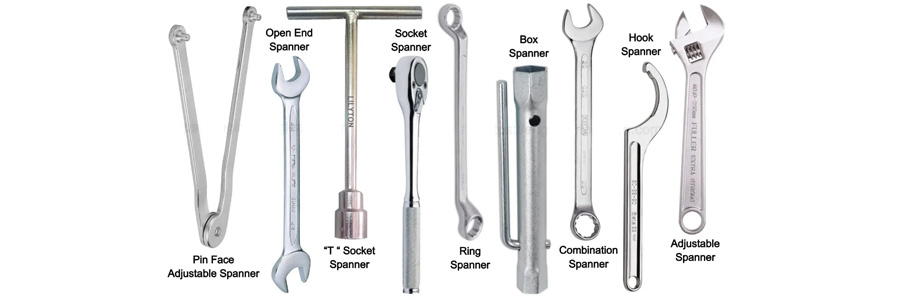

FOXWOLL provides wrenches with different styles and functions to meet any of your working situations. We have Wrench sets, Adjustable wrenches, Ratchet wrenches, Pipe wrenches, Torque wrenches, Hook wrenches, etc. for you to choose from. In addition, we also provide customized services. Send us your product requirements or drawings, and we will reply to you as soon as possible.

Can't Find The Wrench Or Tool Kit You Need?

Contact Us For The Latest Product Catalog

Your Best Quality Wrench Manufacturer and Supplier in China

Foxwoll Tool is a comprehensive enterprise specializing in the production and manufacture of hand tools, and wrenches are our hot-selling products. We have a variety of hot-selling wrench products to choose from. We have a professional team that can provide you with professional customized solutions.

If you are interested in our products and solutions, please feel free to contact us.

In order to meet the different needs of customers for wrenches. We provide customized service. You can provide specific product requirements, and our engineers will design and produce according to your requirements. We can produce for you in terms of material, size, function, color, etc., and provide mold opening services.

● Super Quality Control Management

FOXWOLL, as a professional tool manufacturer in China, perfect quality management is our most basic standard and specification to ensure that the wrench and other tools provided to you have good performance.

● Rich Production Experience

FOXWOLL has 16 years of production experience since its establishment. The pursuit of continuous research and innovation has given us certain advantages in product performance and appearance.

● Competitive Price

FOXWOLL is a Chinese factory. We are committed to becoming the most cost-effective tool exporter in China. Therefore, we not only provide you with high-quality products but also have an advantage in price.

● Perfect After-sales Service

FOXWOLL is a Chinese factory. We are committed to becoming the most cost-effective tool exporter in China. Therefore, we not only provide you with high-quality products but also have an advantage in price.

Related Products

Wrench FAQ Guide

1. What is a wrench tool?

A wrench tool is a mechanical device to grip, turn or hold an object. It typically consists of a handle and jaws connected by a hinge. There are many types of wrenches, each designed for a specific purpose. For example, a pipe wrench is used to grip and turn pipes, while a socket wrench is used to grip and turn nuts and bolts. Wrenches are essential tools for many constructions, repair, and maintenance tasks.

Wrenches come in a variety of sizes, shapes, and designs. The hand wrench is the hand wrench, which is operated by hand. There are also power wrenches powered by electricity or compressed air. These wrenches are typically used in industrial applications where speed and power are more important than precision.

2. What are wrenches made of?

There are many different types of wrenches, each made from other materials. The most common type of wrench is the steel wrench. This is because steel is a solid and durable metal that can withstand a lot of wear and tear. Other wrenches include aluminum wrenches, titanium wrenches, and even plastic wrenches. Each type of wrench has its advantages and disadvantages, so it’s essential to choose the right one for the job.

Some wrenches are made from more than one type of material. For example, a steel wrench may have an aluminum handle. This is because aluminum is very light, so it won’t add much weight to the wrench. However, it’s also not as strong as steel, so it may not be able to withstand as much wear and tear.

Chrome-plated alloy steel is the material of choice for wrenches. This type of steel is strong and durable, making it ideal for use in a tool that will see a lot of wear and tear. The chrome plating also gives the wrench a nice finish that resists rust and corrosion.

3. What is the best material for a wrench?

A wrench is a tool used to apply torque to turn objects. The material of the wrench contributes to its strength and durability. A wrench made of chrome-plated vanadium steel is durable and corrosive-resistant. This type of wrench is ideal for use in industries with harsh conditions, such as oil and gas production. In conclusion, chrome-plated vanadium steel is the best material for a wrench.

4. What is the size of the wrench?

There are many types and sizes of wrenches, depending on what you need the wrench for. A wrench is a tool that provides grip and mechanical advantage in applying torque to turn objects—usually nuts and bolts—that may otherwise be difficult or impossible to turn by hand.

There are many different wrench types, including Allen/hex keys, box-end wrenches, open-end wrenches, adjustable wrenches, pipe wrenches, and torque wrenches. Each type of wrench is designed for a specific purpose. For example, Allen/hex keys tighten or loosen bolts with hexagonal heads, while box-end wrenches apply torque to recessed nuts or bolt heads.

The width of the jaw determines the size of the wrench. The most common sizes are 1/4, 5/16, 11/32, 3/8, 7/16, 1/2, 9/16, 5/8, 11/16, 3/4, 13/16 and 7 / 8 inches. There are also metric wrenches available in sizes 6 through 19. Additionally, there are flare nut wrenches available in sizes 3 / 8 , 7 / 16 , 1 / 2 , 9 / 16 , 5 / 8 , 11 / 16 , 3 / 4 and 7 / 8 . Each wrench can be combined in two sizes.

The size of the wrench also varies depending on the application. For example, a small wrench may be needed to reach bolts in tight spaces, while a giant wrench may apply more torque to loosen a stubborn nut or bolt.

In general, wrenches are available in various sizes to accommodate different applications. So, when selecting a wrench, it is essential to consider the size and type that will best suit your needs.

5. What are the most common types of wrenches?

There are many types of wrenches, but the most common ones are socket wrenches, box-end wrenches, open-end wrenches, and adjustable wrenches. Socket wrenches are used to loosen or tighten bolts and nuts. Box-end wrenches have a closed end that fits around the nut or bolt head. Open-end wrenches have an open end that slips over the sides of the nut or bolt head. Adjustable wrenches can be adjusted to fit different size nuts and bolts.

6. Which wrench is more effective?

Many types of wrenches are available on the market, but which is more effective? Here’s a look at some of the most popular options to help you decide.

Standard Wrench: The standard wrench is the most basic type and is typically steel-made. It is designed to fit over a nut or bolt head and provide torque to loosen or tighten it.

Adjustable Wrench: An adjustable wrench has a movable jaw that can be adjusted to fit over different size nuts and bolts. This makes it a versatile option for many different projects.

Socket Wrench: A socket wrench consists of a handle with a socket attached. The socket can be swapped out to fit over different size nuts and bolts. This type of wrench is typically used with power tools.

Torque Wrench: A torque wrench is a specialized tool that is used to apply a specific amount of torque to a nut or bolt. This is important for projects requiring precise tension, such as engine work.

Impact Wrench: An impact wrench is a power tool that delivers high torque to loosen or tighten nuts and bolts. It is often used in automotive applications where traditional wrenches might struggle.

Ultimately, the best wrench is the one that fits the job at hand. By matching the right tool to the task, you can get the job done more efficiently and with less hassle.

7. What’s the difference between a ratchet and a socket wrench?

There are a few critical differences between ratchet wrenches and socket wrenches. First, ratchet wrenches have a built-in ratcheting mechanism that allows them to turn fasteners without quickly removing and repositioning the wrench. This can be a big time-saver, especially when working on projects with many bolts or screws.

Socket wrenches, however, do not have a ratcheting feature. They’re designed to fit over a fastener and provide extra leverage for turning it. This means you’ll need to remove and reposition the wrench after each turn, which can be more time-consuming than using a ratchet wrench.

Another difference between ratchet wrenches and socket wrenches is the size of the head. Ratchet wrenches typically have a smaller head, which can be helpful when working in tight spaces. On the other hand, socket wrenches have a giant head that provides more surface area for turning.

Finally, ratchet wrenches are often available in metric and standard sizes, while socket wrenches are typically only available in one or the other. So if you’re working on a project that requires both metric and standard-sized fasteners, you’ll need to ensure you have a ratchet wrench that can accommodate both.

8. What are wrench used for?

Wrenches are tools used to apply torque or force to an object. This can be used to loosen or tighten nuts and bolts or to turn other objects such as valves or handles. There are many types of wrenches, each designed for a specific purpose.

The most common type of wrench is the adjustable wrench. This wrench has jaws that can be adjusted to fit around different sizes of nuts and bolts. Another common type of wrench is the ratcheting wrench. This wrench is designed to quickly loosen or tighten nuts and bolts without having to remove the wrench from the object.

There are also specialized wrenches that are designed for use in specific situations. For example, impact wrenches are designed to be used with impact drivers. These wrenches can apply a large amount of torque, making them ideal for loosening stubborn nuts and bolts. There are also pipe wrenches explicitly designed for use on pipes.

When selecting a wrench, it is essential to choose one that is the right size for the job. Wrenches come in various sizes, ranging from very small to very large. It is also essential to select a wrench that is comfortable to hold and that will not slip in your hand.

Wrenches are essential for anyone with machinery or who frequently works with nuts and bolts. By choosing the correct wrench for the job, you can make your work easier and faster.

9. Whats the difference between a wrench and a monkey wrench?

There are several critical differences between wrenches and monkey wrenches. For one, wrenches are designed for various nuts and bolts, while monkey wrenches are only meant to be used with one specific type of nut or bolt. Additionally, wrenches come in various sizes to accommodate different nuts and bolts, while monkey wrenches only come in one size. Finally, wrenches typically have a more extended handle than monkey wrenches, which gives the user more leverage when trying to loosen or tighten a nut or bolt.

10. How to choose a wrench?

There are many types of wrenches available on the market today, so how do you know which one is right for your needs? The first thing to consider is what type of projects you will be using it for. A basic model should suffice if you only need a wrench for occasional light-duty household tasks. However, if you plan on using it for more heavy-duty projects or ones requiring more precise settings, you may want to consider a more advanced model.

Next, take a look at the different sizes of wrenches available. Again, this will depend on what type of projects you plan on using it for. A compact model should be acceptable if you only need a small wrench for light-duty tasks. However, if you need a giant wrench for more heavy-duty projects, you must choose a model accordingly.

Finally, think about the material that the wrench is made out of. Some wrenches are made of steel, while others are made of aluminium. Steel wrenches will be more durable overall, but they will also be heavier. On the other hand, aluminium wrenches will be lighter but not as durable. Again, you will need to consider this based on the type of projects you plan on using the wrench for.

With these factors in mind, choosing the correct wrench for your needs should be relatively easy. Just make sure to take your time and consider all of your options before making a final decision.

11. What is the difference between a spanner and a wrench?

A spanner is a tool to loosen or tighten bolts, while a wrench is used to turn nuts. While both tools are designed to turn objects, each has a different design that makes them better suited for different tasks. For example, spanners typically have a more extended handle than wrenches, giving them more leverage and better suited for loosening bolts. Wrenches, on the other hand, usually have a shorter and sturdier handle, which makes them better suited for tightening nuts.

Spanners and wrenches are both essential tools for anyone who works with machinery or plumbing. While they may seem similar, they each have their unique purposes. Understanding the difference between a spanner and a wrench ensures you have the right tool for the job.

12. How to buy a wrench from FOXWOLL?

If you are buying a wrench from FOXWELL, there are two ways to get it. For the finished product, you need to pay for the final product, then pay, and after factory production, your product will deliver. On the other hand, for customized products, before payment, you need to check the sample, confirm it and make payment once you sign a contract. Then the factory will deliver your product.

13. What services can you enjoy at FOXWOLL?

When you choose to work with FOXWELL, you can enjoy a range of services designed to make your life easier. From competitive prices and perfect after-sales service to personalized and packaging design service, we have everything you need to get the most out of your investment. Plus, our comprehensive quality control and one-to-one customer service mean you can always be sure you’re getting the best possible value for your money.

14. If you are an e-commerce operator, what can FOXWOLL do for you?

If you are an e-commerce operator, you will get product customization services from FOXWELL. We will customize packaging for your product as per your demand.

15. How to check the quality of FOXWOLL products?

If you want to check the product, FOXWELL offers a free sample. Also, with the professional inspection team, we ensure the quality of the product.